Speedy, Safe, Cost Effective Contractor Solutions

When it comes to rail infrastructure it’s the Contractors job to deliver to spec within tight deadlines. Often with limited track possession time or project time phases. Always within budget. And always with safety an absolute priority.

Whether it’s maintenance, renewals, enhancements or a major greenfield project, effective and efficient supply chain operations play a major role in mitigating risks and making sure projects are always delivered safely, profitably and on time.

Contractor Focused Supply Chain Efficiencies

Our work with contractors has identified many opportunities to make improvements to the supply chain and materials management – to mitigate project risk, improve operational performance and optimise costs. Just some of the benefits an improved supply chain delivers include:

Challenges such as how to:

- Improving the efficiency of materials stores and materials handling to ensure materials are where they are needed when they are needed

- Optimised resource and systems provision to better manage the supply chain and materials

- Minimising inventory costs and balancing inventory against project needs. Inventory is often over or understocked against project requirements whilst obsolete stock clogs stores space

- Improving materials access and control, including end-of-project management, storage and disposal

- Ensuring worker safety

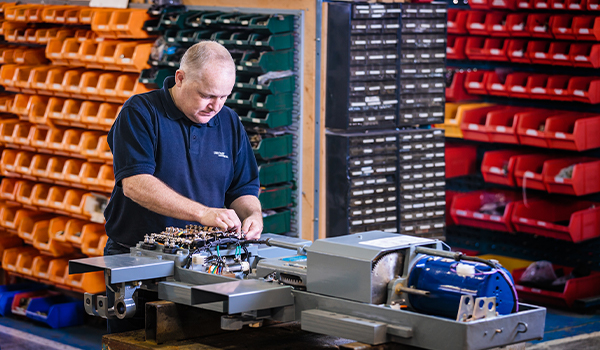

- Removal of onsite handling, assembly and testing to improve site safety and operational efficiency ALT: Moving assembly and testing to our off-site factories to release marshalling location space and reduce the cycle time between delivery and installation

- Repair and Rotable Management

Why you should use Unipart Rail?

Every project is different. Unipart Rail’s collaborative innovation provides contractors with the quality materials and services you need when and where they are needed – all delivered and configured in flexible, customised solutions that save time, reduce project risks and optimise costs.

Product and technological innovation that contractors use themselves and deliver to their clients. Improved point of use materials availability that reduces inventory costs.

- Improved availability of parts - available just in time where they are needed

- Products and parts backed by our safety and quality assurance processes, technical support and warranty

- Lean operations and a more efficient supply chain for maintenance operations - consolidated supply and just in time parts availability, when and where they are needed, at the point of use

- Innovation in technology and processes that improves operational and business performance. Innovative solutions that can help meet the challenges around cost, capacity, customers and carbon

- Asset Management Solutions including, repair and overhaul services, obsolescence management and CBM technology to reduce maintenance costs and improve train availability

Case Studies...

Unipart Rail’s service is underpinned by significant investment in processes, systems and a team specialising in new product development, customer service, supplier management and engineering. Our dedicated engineering team ensures supplied products are safe and meet both standards and legislative requirements.

Our continual innovation and investment in people and systems sees us lead in the development of the Condition Based Supply Chain to deliver new freight fleet management efficiencies.

Balfour Beatty

Remote Warehouse

stockholding by 95% and stock value

by over £140,000 within a year, with

availability and performance increasing

at the same time.

for VolkerRail, providing them with a continuous supply of materials and full support during a Christmas ‘blockade’.

VolkerRail

Supply Chain Services

solution for The Staffordshire Alliance to

solve the problems they faced when fabricating and storing complex overhead line equipment.

Staffordshire Alliance

Offsite Factory