Train Owner Case Studies

Door

Diagnostics

remote monitoring of train doors through

the use of inductively coupled telemetry.

It is a low cost solution that delivers “health indicators” on the doors that allow effective

and targeted interventions to be made.

monitoring solution based around

their proven Diagnostic Hub,

which is in use on multiple fleets

in the UK for condition monitoring.

ScotRail

Data into information

of materials that would reduce time, procurement activities and storage optimisation. Unipart Rail’s kitting system significantly reduced the

time taken to complete the overhaul operation.

Eurostar

Re-usable kitting solution

Hinged

Light Diffusers

Northern Rail had a number of reported

driver complaints about draughts

in the driver’s cab of the Class 150 vehicles.

Unipart Rail provided a solution to the

challenge through the design of a new diffuser panel.

Code

Conversion Unit

has been proven in service to improve

reliability, reduce power consumption,

reduce mass and reduce potential

failure modes.

from Finland, were set the challenge of

developing a new damper to replace the

existing Woodhead and Pegasus units,

fitted to BT 10 bogies.

Dampers

for B10 Bogie (MK3 Fleets)

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

TPWSfour For ETCS

equipped trains

Unipart Rail’s TPWSfour and AWS systems, which are designed and manufactured in house, are equipped with the latest Evo control unit are fully compatible with the rail industry standards and ETCS requirements and have proven high levels of reliability in service.

Train Operating Company Case Studies

Freightliner

SmartServe Solution

were opening a new depot and were looking for

an innovative solution that would support their maintenance activities. Unipart Rail’s SmartServe solution provides a flexible and scalable solution that can be fine-tuned to customer requirements.

Unipart Rail’s World Class depot stores facility

was operational in less than 3 months,

delivering fantastic results including 98% stock accuracy, 97% availability and 50%

reduction in defects.

Northern Rail

Depot Stores Management

and effectiveness of South West Train’s stores, enabling them to improve their service to production and reducing visits to the stores by 54%.

South West Trains

Lean Depot Stores

Irish Rail

Transforming the Supply Chain

Following a diagnostic, a programme was developed to work with Iarnród Eireann employees to deliver improvements across the Supply Chain and develop their own Lean internal capability.

Metro Trains Melbourne PTY ltd approached Unipart Rail’s Expert practitioners to complete a diagnostic across their total supply chain, using their structured and standardised approach.

MTM

Supply Chain Diagnostics

undertake a diagnostic study at their light maintenance depot stores operations.

Results included costs savings of 20% and increased material availability to 98%.

Sydney Trains

Depot Stores Diagnostic

Yarra Trams

Visualisation Hub

The imminent move to a new head office

building presented an opportunity for a

dedicated visualisation room for this

purpose, with the aim to cascade this

model throughout the business.

Chiltern Railways

Wildlife Garden Project

area to both encourage wildlife to return,

and to provide an area where depot

colleagues could take breaks away from

the working environment in a calm and

pleasant space.

TrackPan Installation at

Perth Train Depot

A bespoke solution for waste water management for a customer installing a new train wash facility in Perth train depot.

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

TPWSfour For ETCS

equipped trains

Unipart Rail’s TPWSfour and AWS systems, which are designed and manufactured in house, are equipped with the latest Evo control unit are fully compatible with the rail industry standards and ETCS requirements and have proven high levels of reliability in service.

Compressor Service/

Refurbishment

Compressors were a completely new product stream for our business, but our skills in creating new overhaul processes, test procedures and developing staff skills meant that this was a straightforward challenge for us.

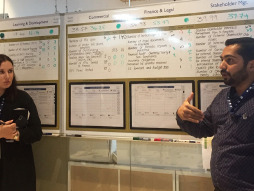

CAMCO Visualisation

Centre

A Visualisation Centre was implemented and CAMCO employees were trained in Lean Tools and Techniques, Visual Management and Effective team meetings.

Freight Operating Company Case Studies

Freightliner

SmartServe Solution

were opening a new depot and were looking for

an innovative solution that would support their maintenance activities. Unipart Rail’s SmartServe solution provides a flexible and scalable solution that can be fine-tuned to customer requirements.

Northern Rail

Depot Stores Management

Unipart Rail’s World Class depot stores facility

was operational in less than 3 months,

delivering fantastic results including 98% stock accuracy, 97% availability and 50%

reduction in defects.

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

TPWSfour For ETCS

equipped trains

Unipart Rail’s TPWSfour and AWS systems, which are designed and manufactured in house, are equipped with the latest Evo control unit are fully compatible with the rail industry standards and ETCS requirements and have proven high levels of reliability in service.

Train Builder Case Studies

Siemens

Performance through Engagement

Siemens Traincare staff attended

Unipart Expert Practices 1 week

Lean Academy, to learn how to

implement lean tools and techniques

within their project. Results include

98% increase in material availability.

Our engineers went back to basics

and redesigned the TPWSfour

system to develop its functionality.

TPWSfour

Product Innovation

undertake a diagnostic study at their light maintenance depot stores operations.

Results included costs savings of 20% and increased material availability to 98%.

Door Diagnostics

Axle Storage

2 and 4 set

The design and manufacturing challenge was to create train axle storage units that could accommodate 2 or 4 axle sets that offered full protection of the axle and was stackable 5 high.

Falcon 2

Rail Lifting Hoist

Ferrartis were asked to improve the design and performance of an existing winch which was used on the front of a track maintenance vehicle to lift rails.

The storage of wheelsets has traditionally been on racking that does not allow for the easy inspection and rotation of the wheels.

Dynamic Wheelset

Carrier Systems

UGL Maintrain

Supply Chain Diagnostic

Unipart Rail worked with the UGL Maintrain

team to complete a Diagnostic activity in

order to understand how the Supply Chain operation could be improved.

Siemens

Spares Support Bogie overhaul

Unipart Rail was awarded a prestigious

contract to overhaul Siemens Class 444

bogies at its Production Business Unit (PBU)

in Doncaster. The requirement was to overhaul 450 bogies over a period of 13 months

The biggest tram depot redevelopment in Melbourne’s history transformed Preston Workshops into a state-of-the-art facility for new generation E-Class trams.

Yarra Trams

Transformation

Southern

Performance Through Engagement

Southern Railway approached Unipart to

conduct a strategic review of their spares

and storage capacity across all of their four depots, with the objective of generating a

storage strategy that would meet the changing needs of the business, without a major

investment in capital.

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

TPWSfour For ETCS

equipped trains

Unipart Rail’s TPWSfour and AWS systems, which are designed and manufactured in house, are equipped with the latest Evo control unit are fully compatible with the rail industry standards and ETCS requirements and have proven high levels of reliability in service.

Rolling Stock Maintainer and Overhauler Case Studies

Freightliner

SmartServe Solution

were opening a new depot and were looking for

an innovative solution that would support their maintenance activities. Unipart Rail’s SmartServe solution provides a flexible and scalable solution that can be fine-tuned to customer requirements.

Dampers

for B10 Bogie (MK3 Fleets)

from Finland, were set the challenge of

developing a new damper to replace the

existing Woodhead and Pegasus units,

fitted to BT 10 bogies.

and effectiveness of South West Train’s stores, enabling them to improve their service to production and reducing visits to the stores by 54%.

South West Trains

Lean Depot Stores

Siemens

Performance through Engagement

Siemens Traincare staff attended

Unipart Expert Practices 1 week

Lean Academy, to learn how to

implement lean tools and techniques

within their project. Results include

98% increase in material availability.

As a result of the Unipart Rail programme, Northern Rail have produced excellent improvements in reliability and availability. These include 50% reduction in open defects and 46% reduction in time

Northern

Performance through Engagement

Due to the old version of TCAIDs becoming obsolete, the route services team worked with Unipart Rail to re-engineer the equipment by removing the older, unreliable circuitry and replacing it with digital components that provide far greater resilience.

Wessex Leaf-Fall Track Circuit Solution

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

CAMCO Visualisation

Centre

A Visualisation Centre was implemented and CAMCO employees were trained in Lean Tools and Techniques, Visual Management and Effective team meetings.

Contractor Case Studies

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

Balfour Beatty

Remote Warehouse

stockholding by 95% and stock value

by over £140,000 within a year, with

availability and performance increasing

at the same time.

VolkerRail

Supply Chain Services

for VolkerRail, providing them with a continuous supply of materials and full support during a Christmas ‘blockade’.

Staffordshire Alliance

Offsite Factory

solution for The Staffordshire Alliance to

solve the problems they faced when fabricating and storing complex overhead line equipment.

Babcock

Commissioning Spares

Babcock was delivering the Coleraine to Derry~ Londonderry project in Northern Ireland and needed a reliable supply chain provider to support the entire project delivery.

London Underground

Depot Management

Unipart Rail created a ‘Model Line’ satellite depot for London Underground. The new system provided them with Underground with greater understanding of their ‘product flow’ procedures and the practicality of the depot layout was drastically improved.

Atkins

Feltham Project

The project required improved material controls

to provide a more efficient process for material location and identification when on site.

Atkins

Relocatable Equipment Buildings

Unipart Rail’s specially designed equipment minimises trackside installation time and the carefully co-ordinated logistics process ensures a safe environment for all workers.

Atkins

Feltham Emergency Materials

The Feltham Phase 1 project took place over a 12-18 month period and was segregated into individual work packages, with time bound critical delivery schedules.

Infrastructure Owner Case Studies

Collaborative Working

and 44001

In response to industry and customer

needs, Unipart Rail has been certified

firstly to the BS11000 and then to the

subsequent ISO 44001 standard for

Collaborative Business Relationship

Management Systems.

Network Rail

Partnering Renewals

During the Wigan to Preston Blockade,

Unipart Rail’s procurement and supplier management skills, meant that all materials

were procured, and made available

at the right places, at the right time.

Zero

Maintenance Signalling

for signals in locations where they are exposed

to free falling rain. It is estimated that this will reduce maintenance costs by over £4,061,000

over the life of the signals.

Babcock

Commissioning Spares

Derry~ Londonderry project in

Northern Ireland and needed a reliable

supply chain provider to support the

entire project delivery.

Network Rail

Point Machine Refurbishment

machine repair process has achieved a

cost-saving for Network Rail of £750,000

against the purchase of new machines,

an overall saving of 50%.

MTM

Supply Chain Diagnostics

Metro Trains Melbourne PTY ltd approached Unipart Rail’s Expert practitioners to complete a diagnostic across their total supply chain, using their structured and standardised approach.

WigWag Innovation

Centres of Excellence to develop a

complete new WigWag which not only

had much higher luminous intensity,

but also an improved ‘tilt’ mechanism

for local adjustment.

Alstom

Materials Reclamation

When Alstom were planning to de-mobilise

their Peterborough stores, they turned to

Unipart Rail to manage the process

London Underground

Depot Management

Unipart Rail worked closely with Balfour

Beatty to identify their precise material requirements, by helping the customer

to focus on their exact needs, it eliminated

over-stocking and allowed the stores to be arranged in a logical way.

Sydney Trains Order Process

The objective of this project was to reduce

lead time of product from a customer

order being received at the REC to

the material being available for collection

by the customer.

Sydney Trains

Skill Capture

The Rail Equipment Centre (REC) had identified

a business risk due to an aging workforce with either none or very little capture of skills for the manufacture /overhaul of its products..

Atkins

Feltham Project

The project required improved material

controls

to provide a more efficient

process for material location and

identification when on site.

Wessex Leaf-Fall Track Circuit Solution

Due to the old version of TCAIDs becoming obsolete, the route services team worked with Unipart Rail to re-engineer the equipment by removing the older, unreliable circuitry and replacing it with digital components that provide far greater resilience.

PSPs and ASPs for

East of Leeds

As part of the TRU Alliance Project, Samuel James Engineering designed and manufactured Principal Supply Points (PSPs) and Auxiliary Supply Points (ASPs) for Volker Rail.

Atkins

Feltham Emergency Materials

The Feltham Phase 1 project took place over a 12-18 month period and was segregated into individual work packages, with time bound critical delivery schedules.

Sehurst REB

upgraded Manufacture

Network Rail identified there was severe CAT 4 wire degradation within an REB at London’s Selhurst Depot and reached out to Unipart Rail.